ASTM A182 Gr.S32100 Forged Round bar

This page provides ASTM A182 Gr.S32100 stock for Round bar, Flat bar, Sheet. Datasheet - mechanical properties, ASTM A182 Gr. F321 chemical element,ASTM A182 Gr.S32100 performance specifications.

| Product parameters | |

| Material Technical Standards:: | ASTM A182 / A276 / A240 |

| Terms of Price:: | Ex works / CIF / CFR |

| Heat Treatment Practice:: | Untreated or solution annealed 1050 ℃, water or air cooled |

| Standard Export Packing Way:: | Wooden box, pallet / tray free from fumigation |

| Production Lead Time:: | Within 25 days after 30% deposit prepayable |

| ISO 9001-2015 Certified by:: | UKAS |

| Company ISO Register No:: | UQ211218R0 |

Description

PRODUCT MELTING & AVAILABLE DIMENSIONS

The alloy is usually produced by BEF & BEF + AOD & EAF + VD + LF, followed by electroslag refining (ESR or VAR ) if necessary for special purpose.

Bars and, where applicable, forgings are subjected to ultrasonic examination based on the different levels according to the buyers' specific requirements.

Round bar / Wire rod (Diameter): 5.5mm ~ 700mm

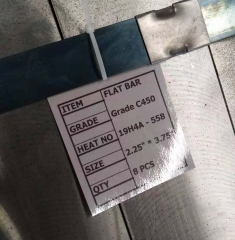

Square bar / Flat bar: 10mm to 650mm

Heavy/middle plate via hot rolled: T60 ~ 400 X W60 ~ 1200 X L1000 ~ 3500mm

Forging piece: stepped shafts / other different shapes based on OEM.

TECHNICAL DATA SHEET - ASTM A182 Grade S32100

MATERIAL TECHNICAL STANDARDS - ASTM A182 - 2018

MATERIAL TYPE - 18Cr 10Ni Austenitic Stainless steel

CHEMICAL COMPOSITION (mass weight %) Grade S32100

C (%): ≤ 0.08, Mn (%): ≤ 2.00, Si (%): ≤ 1.00, P (%)≤: 0.030, S (%)≤: 0.010

Ni (%): 9.0 ~ 12.0, Cr (%): 17.0 ~ 19.0, Mo (%): -, Nb (%): -, N (%): ≤ 0.10

Ti (%): 5 X C ~ 0.70, Fe (%): Remainder

MECHANICAL PROPERTY UNDER ROOM TEMP.

Tensile strength, σb/≥ MPa: 515

Yield strength, σ0.2/MPa: 205

Elongation, δ ≥(%): 30.0

Reduction of area, ф ≥ (%): 50.0

Hardness via heat treatment /HBW: -

HEAT TREATMENT PRACTICE

Condition: solution annealing

Cooling medium: water or oil cooling

Tempering temperature: 1080 ~ 1180 Deg.C

The alloy is usually produced by BEF & BEF + AOD & EAF + VD + LF, followed by electroslag refining (ESR or VAR ) if necessary for special purpose.

Bars and, where applicable, forgings are subjected to ultrasonic examination based on the different levels according to the buyers' specific requirements.

Round bar / Wire rod (Diameter): 5.5mm ~ 700mm

Square bar / Flat bar: 10mm to 650mm

Heavy/middle plate via hot rolled: T60 ~ 400 X W60 ~ 1200 X L1000 ~ 3500mm

Forging piece: stepped shafts / other different shapes based on OEM.

TECHNICAL DATA SHEET - ASTM A182 Grade S32100

MATERIAL TECHNICAL STANDARDS - ASTM A182 - 2018

MATERIAL TYPE - 18Cr 10Ni Austenitic Stainless steel

CHEMICAL COMPOSITION (mass weight %) Grade S32100

C (%): ≤ 0.08, Mn (%): ≤ 2.00, Si (%): ≤ 1.00, P (%)≤: 0.030, S (%)≤: 0.010

Ni (%): 9.0 ~ 12.0, Cr (%): 17.0 ~ 19.0, Mo (%): -, Nb (%): -, N (%): ≤ 0.10

Ti (%): 5 X C ~ 0.70, Fe (%): Remainder

MECHANICAL PROPERTY UNDER ROOM TEMP.

Tensile strength, σb/≥ MPa: 515

Yield strength, σ0.2/MPa: 205

Elongation, δ ≥(%): 30.0

Reduction of area, ф ≥ (%): 50.0

Hardness via heat treatment /HBW: -

HEAT TREATMENT PRACTICE

Condition: solution annealing

Cooling medium: water or oil cooling

Tempering temperature: 1080 ~ 1180 Deg.C