1.2741 / 55CrNiMoVS4-2-4 Tool Steel Round Bars

| Product parameters | |

| Place of origin:: | P.R.China |

| Terms of price:: | Ex woks, CNF, CFR, DDU |

| Min. order quantity:: | 20000 KG |

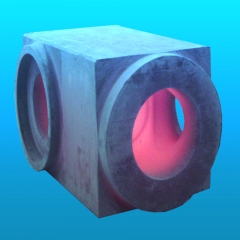

| Product shapes:: | Round bar, flat bar, plate and forgings |

| Ultrasonic test standard:: | ASTM E2375 / MIL-STD- AMS 2154 / SEP 1923 / GB/T 4162 / EN 10228-3 / EN 10308 |

| Standard export packing way:: | Wooden box, pallet / tray free from fumigation |

| Production lead time:: | Within 75 days after 40% deposit prepayable |

| Unified social credit code:: | 91510784777942750J |

| Company ISO register No.:: | 04321Q32740R0S |

Description

TYPICAL APPLICATIONS

Cutting tools. Mechanical parts, Air hammer tools. Piercing tools.

ADVANTAGE & SUPERIOR SERVICE

20+ years Focus On Special Steel Manufacturing and processing.

Stock over 60 grades with a competitive price, along with cutting service for specific requirement.

Customizing special material is welcome.

Round bar (Diameter): 5.5 to 500mm

Flat bar (Thickness X width): 10 ~ 350 X 15 ~ 850 X Lmm

Heavy plate (Thickness X width): 60 ~ 400 X 80 ~ 1000 X Lmm

Length: fixed length, random length or based on the customer's special requirement.

CHEMICAL COMPOSITION (mass weight %)

C (%): 0.53 ~ 0.58, Si (%): 0.10 ~ 0.35, Mn (%): 0.70 ~ 0.90, P (%)≤: 0.030, S (%)≤: 0.015

Cr (%): 0.90 ~ 1.10, Ni (%): 0.45 ~ 0.60, Mo (%): 0.38 ~ 0.48

V (%): 0.03 ~ 0.10, Fe (%): remainder..

MECHANICAL PROPERTIES - HEAT TREATMENT CYCLE - HARDNESS

Hot working tenperature /℃: 1050 ~ 850

Annealing temperature /℃: 650 ~ 700

Hardness after annealing ≤HBW: 25Quenching temperature /℃: 830 ~ 870

Cooling medium: air or oil

Common tempering temperature /℃: 160 ~ 300

Hardening value after tempering at temperature /MPa | 100℃: HRC 56