X50NiCrWV13-13 ESR Ingot, 1.2731 Forgings

| Product parameters | |

| Material category:: | Alloy 13.0Cr - 13.0Ni-2.0W Hot Working Tool Steel |

| Stock & Inventory available:: | Round bar Diam. 20 ~ 160mm, and ESR Ingot |

| Melting process way:: | BEF + VD + ESR |

| Min. order quantity:: | 200 KG |

| Ultrasonic test standard:: | ASTM E2375 / MIL-STD- AMS 2154 / SEP 1923 / GB/T 4162 / EN 10228-3 / EN 10308. |

| Company ISO register No.:: | UQ211218R0 |

Description

RAW MATERIAL DATASHEET - W-Nr 1.2731

STOCK AVAILABLE ON HAND - ESR ingot, Round bar Diam. 20 ~ 200mm

Material Category - Hot working tool steel

Material Specifications - EN ISO 4957: 2000 , DIN 17350 (1980)

Main Chemical Elements (mass weight - %)

Carbon, C (%): 0.45 ~ 0.55, Silicon, Si (%): 1.20 ~ 1.50, Manganese, Mn (%): 0.60 ~ 0.80

Phoshorus, P (%) ≤: 0.035, Sulfur, S (%) ≤: 0.035

Chromium, Cr (%): 12.0 ~ 14.0, Molybdenum, Mo (%): -, Vanadium, V (%): 0.30 ~ 1.00

Nickel, Ni (%): 12.5 ~ 13.5, Tungsten, W (%): 1.50 ~ 2.80

MECHANICAL PROPERTIES & HEAT TREATMENT

Hot working tenperature ℃: 1050~850

Annealing temperature ℃: -

Hardness after annealing ≤HBW: 300

Quenching temperature ℃: 980 ~ 1030

Cooling medium: Oil

Common tempering temperature ℃: 400 ~ 600

Round bar / Disc (diameter1): 5.5mm to 700mm

Square bar / Flat bar: 10mm to 600mm

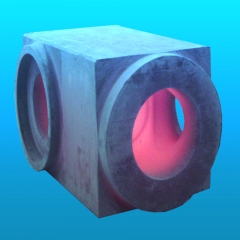

Forging piece: stepped shafts, other different shapes based on OEM.