1.2705 / 80NiCr11 Cold work Ni-Cr Tool Steel

Alloy tool steel is widely used to produce the cutting tool, cold/heat distortion mould and measuring implement. and further to manufacture the piston, valve, valve seat of fuel pump.

| Product parameters | |

| Place of origin:: | P.R. China |

| Terms of price:: | Ex works, CIF, CFR |

| Min. order quantity:: | 1300 KG |

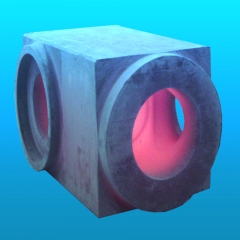

| Product shapes:: | Round bars, flat bars, forgings, ring |

| Production lead time:: | Within 55 days after 40% deposit prepayable |

| Unified social credit code:: | 91510871777942750J |

| Company ISO register No.:: | UQ211218R0 |

Description

TYPICAL APPLICATIONS

Cutting tools. Mechanical parts, Air hammer tools. Piercing tools.

Main Chemical compositions (mass weight %)

C (%): 0.75 ~ 0.85, Si (%): ≤ 0.40, Mn (%): 0.20 ~ 0.40,

P (%)≤: 0.025, S (%)≤: 0.020

Cr (%): 0.20~ 0.25, Ni (%): 2.40 ~ 2.90, Fe (%): remainder

Heat treatment Practice, Mechanical Properties Under Room Temperature

Hot working tenperature /℃: 1150 ~ 900

Annealing temperature /℃: 720 ~ 750

Hardness after annealing ≤HBW: 248

Quenching temperature /℃: 810 ~ 840

Cooling medium: oil

Common tempering temperature /℃: 150 ~ 510

Hardening value after tempering at temperature /MPa | 100℃: 60

Hardening value after tempering at temperature /MPa | 200℃: -

Hardening value after tempering at temperature /MPa | 300℃: -

Hardening value after tempering at temperature /MPa | 400℃: -

Advantage and Superior Service

20+ years Focus On Special Steel Manufacturing and processing.

Stock over 60 grades with a competitive price, along with cutting service for specific requirement.

Customizing special material is welcome.

Forms and Dimensions

Round bar (Diameter): 5.5 to 400mm

Steel strip: THK0.15 ~ 2.50 X W5.0 ~ 200mm

Flat bar (Thickness X width): 10 ~ 350 X 15 ~ 600mm

Length: Fixed length or random length or based on the customer's special requirement.