AISI M2 / T11302 High Speed Steel

| Product parameters | |

| Material Category:: | Tungsten-Molybdenum type High Speed Steel |

| Place of Origin: | P. R. China |

| Stocklist & Inventory Available:: | Round bar Diam. 3mm ~ 55mm |

| Min. order quantity Per Batch:: | 500 KG |

| Production Lead Time:: | Within 15 days after 30% downpayment. |

| Unified Social Credit Code:: | 91510871777942750J |

| Company ISO Register No:: | UQ211218R0 |

Description

AISI M2 / T11302 Steel is molybdenum based high-speed steel in tungsten–molybdenum series. T11302 / M2 is a medium alloyed high speed steel which has good machinability. its chemical composition gives a good combination of well-balanced toughness, wear resistance and red hardness properties. Widely used for cutting tools such as twist drills, taps, milling cutters, saws, knives etc. Also commonly used in cold work punches and dies and cutting applications involving high speed and light cuts.

The alloy is usually produced by EAF & AOD followed by electroslag remelting (ESR) / VAR if necessary for special purpose. Bars and, where applicable, forgings are subjected to ultrasonic examination based on the different levels according to the buyers' requirements.100% Ultrasonic test ASTM E2375 /SAE AMS 2154 /SEP 1923 /GB/T 4162 /EN 10228-3.

Bars are usually supplied black/bright in the annealed condition.

Main chemical composition (mass weight %)

P(%) ≤ 0.030, S (%) ≤ 0.030

Cr (%) 3.50 ~ 4.00, Ni (%) - , Mo(%) 4.50 ~ 5.50,W (%) 5.50 ~ 6.75

V (%): 0.30 ~ 0.50, Fe (%): remainder

| Condition of heat treatment | annealing |

| Tensile Rm (MPa) | - |

| Yield Rp0.2 (MPa) | - |

| Elongation A (%) | - |

| Reduction in cross section on fracture Z (%) | - |

| Impact AKV/AKU (J) | - |

| Brinell Hardness (HBW) | 212 ~ 241 |

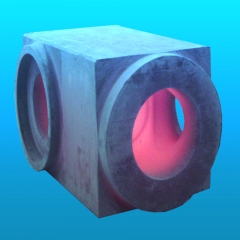

| Shapes and dimensions Round bar (Diameter): 5.50 ~ 650mm Square bar / Flat bar: 3 ~ 650mm Wire rod (Diameter): 0.10 ~ 16mm Forging piece: Different shapes based on OEM |