UNS T51603 / P3 Low Alloy Tool Steel

| Product parameters | |

| Material Technical Standards:: | ASTM A681 - 2004 |

| Min. order quantity Per Batch:: | 3300 kg |

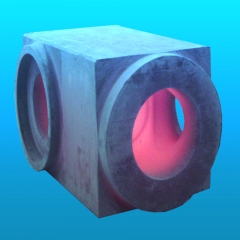

| Product Shapes:: | Round bars, flat bars, ring, valve body |

| Surface Condition:: | Rough turned, shot blasted, centre ground |

| Ultrasonic Test Standard:: | EN 10308, MIL-STD-AMS 2154 CLA |

| Production Lead Time:: | Within 55 days after 40% deposit prepayable |

| Unified Social Credit Code:: | 91510871777942750J |

| Company ISO Register No:: | UQ211218R0 |

Description

| C (%) | ≤ 0.10 |

| Si(%) | ≤ 0.40 |

| Mn(%) | 0.20 ~ 0.60 |

| P(%) | ≤ 0.030 |

| S (%) | ≤ 0.030 |

| Cr (%) | 0.40 ~ 0.75 |

| Ni (%) | 1.00 ~ 1.50 |

| Mo(%) | - |

| Other (%) | - |

| Condition of heat treatment | annealing |

| Tensile Rm (MPa) | - |

| Yield Rp0.2 (MPa) | - |

| Elongation A (%) | - |

| Reduction in cross section on fracture Z (%) | - |

| Impact AKV/AKU (J) | - |

| Brinell Hardness (HBW) | 109 ~ 137 |

| Shapes and sizes: Round bar (Diameter): 5.50 ~ 650mm Square bar / Flat bar: 3 ~ 650mm Wire rod (Diameter): 0.10 ~ 16mm Steel strip via cold rolled: T0.1 - 3mm X W5 - 650mm X L (or in coil form) Forging piece: Different shapes based on OEM |