UNS T61206 / L6 Low alloy Tool Steels

| Product parameters | |

| Place of Origin: | P. R. China |

| Melting Process Route:: | EAF + LF + VD / + ESR, BEF + ESR |

| Min. order quantity Per Batch:: | 3300 KG |

| Ultrasonic Test Standard:: | ASTM E2375 / MIL-STD- AMS 2154 / SEP 1923 / GB/T 4162 / EN 10228-3 / EN 10308. |

| Standard Export Packing Way:: | Wooden box, wooden Pallet / tray with free from fumigation. |

| Company ISO Register No:: | UQ211218R0 |

Description

| C (%) | 0.65 ~ 0.75 |

| Si(%) | 0.20 ~ 0.40 |

| Mn(%) | 0.25 ~ 0.85 |

| P(%) | ≤ 0.030 |

| S (%) | ≤ 0.030 |

| Cr (%) | 0.65 ~ 0.85 |

| Ni (%) | 1.25 ~ 2.00 |

| Mo(%) | ≤ 0.25 |

| Other (%) | V ≤ 0.25 |

| Condition of heat treatment | annealing |

| Tensile Rm (MPa) | - |

| Yield Rp0.2 (MPa) | - |

| Elongation A (%) | - |

| Reduction in cross section on fracture Z (%) | - |

| Impact AKV/AKU (J) | - |

| Brinell Hardness (HBW) | 183 ~ 212 |

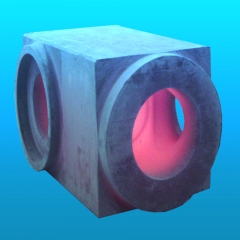

| Shapes and dimensions: Round bar (Diameter): 5.50 ~ 650mm Square bar / Flat bar: 3 ~ 650mm Wire rod (Diameter): 0.10 ~ 16mm Steel strip via cold rolled: T0.1 - 3mm X W5 - 650mm X L (or in coil form) Forging piece: Different shapes based on OEM |