AISI P6 / UNS T51606 ESR Quality Tool Steel

| Product parameters | |

| Material Technical Standards:: | ASTM A681 - 2004 |

| Place of Origin: | P.R. China |

| Certification:: | MTR, COC, Certificate of origin, Form A/E, Invoice, Packing list |

| Product Shapes:: | Round bars, flat bars, forgings, ring |

| Production Lead Time:: | Within 65 days after 40% deposit prepayable |

| Company ISO Register No:: | UQ211218R0 |

Description

The alloy is usually produced by BEF & AOD followed by electroslag remelting (ESR) / VAR if necessary for special purpose. Bars and, where applicable, forgings are subjected to ultrasonic examination based on the different levels according to the buyers' requirements. Bars are usually supplied black/bright in the annealed condition.

| C (%) | 0.05 ~ 0.15 |

| Si(%) | 0.10 ~ 0.40 |

| Mn(%) | 0.35 ~ 0.70 |

| P(%) | ≤ 0.030 |

| S (%) | ≤ 0.030 |

| Cr (%) | 1.25 ~ 1.75 |

| Ni (%) | 3.25 ~ 3.75 |

| Mo(%) | - |

| Other (%) | - |

| Condition of heat treatment | annealing |

| Tensile Rm (MPa) | - |

| Yield Rp0.2 (MPa) | - |

| Elongation A (%) | - |

| Reduction in cross section on fracture Z (%) | - |

| Impact AKV/AKU (J) | - |

| Brinell Hardness (HBW) | 207 |

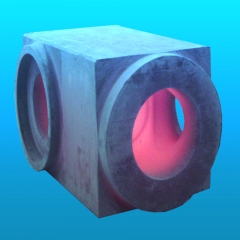

| Forms and Dimensions: Round bar (Diameter): 5.50 ~ 550mm Square bar / Flat bar: 3 ~ 600mm Steel strip via cold rolled: T0.1 - 3mm X W5 - 650mm X L (or in coil form) Forging piece: Different shapes based on OEM |