UNS T13102 / M2 HSS Tool Steel

| Product parameters | |

| Material Category:: | Tungsten Molybdenum type High Speed Steel |

| Place of Origin: | P. R. China |

| Product Shapes:: | Round bar, Flat bar, Plate |

| Standard Export Packing Way:: | Wooden box, wooden Pallet / tray with free from fumigation. |

| Production Lead Time:: | Within 15 days after 30% downpayment. |

| Unified Social Credit Code:: | 91510871777942750J |

| Company ISO Register No:: | UQ211218R0 |

Description

| UNS T13102 (AISI M2) is a general purpose molybdenum-type high-speed steel exhibiting well-balanced toughness, wear-resistance and red hardness properties. This grade is commonly used in cold work punches and dies and cutting applications involving high-speed and light cuts The alloy is usually produced by BEF & AOD followed by electroslag remelting (ESR) / VAR if necessary for special purpose. Bars and, where applicable, forgings are subjected to ultrasonic examination based on the different levels according to the buyers' requirements. 100% Ultrasonic test ASTM E2375 /SAE AMS 2154 /SEP 1923 /GB/T 4162 /EN 10228-3. Bars are usually supplied black/bright in the annealed condition. |

Chemical Composition (mass weeight %)

V 0.30 ~ 0.50

| Condition of heat treatment | annealing |

| Tensile Rm (MPa) | - |

| Yield Rp0.2 (MPa) | - |

| Elongation A (%) | - |

| Reduction in cross section on fracture Z (%) | - |

| Impact AKV/AKU (J) | - |

| Brinell Hardness (HBW) | 212 ~ 241 |

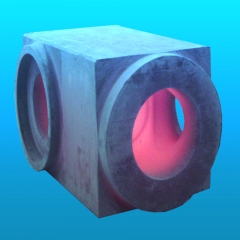

| Shapes and Dimensions Round bar (Diameter): 5.50 ~ 650mm Square bar / Flat bar: 3 ~ 650mm Wire rod (Diameter): 0.10 ~ 16mm Steel strip via cold rolled: T0.1 - 3mm X W5 - 650mm X L (or in coil form) Forging piece: Different shapes based on OEM |